Plastic

Capabilities

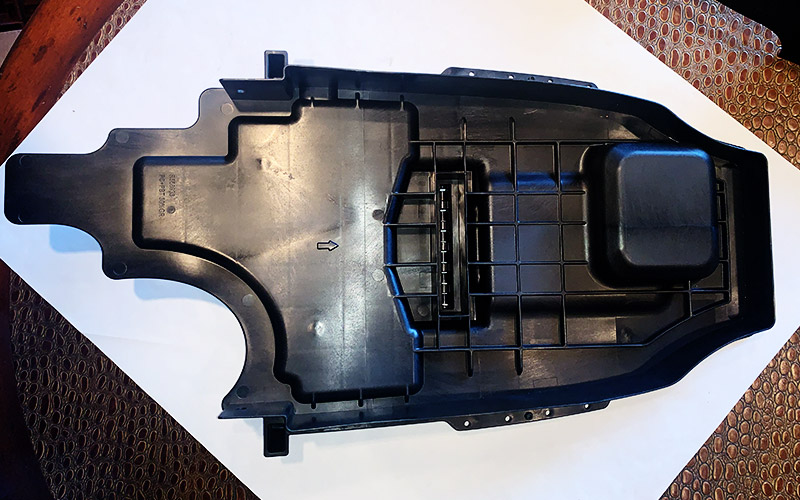

INJECTION MOLDED

- Machines ranging from 55 – 3,300 tons

- Two and Three Shot Molding and Overmolding

- iMFLUX Process Technology (www.imflux.com)

- Rapid Prototypes

- Domestic and Foreign Tool Management

- Automated Assembly and Packaging

- Decorating & Assembly (multiple secondary operations)

- In-Mold Labeling and Decorating

- Mold Flow Simulations

- Structural Foam Capabilities

Materials

- Wide range from common to Engineered resins

EXTRUSIONS

Materials

- Thermoplastics (TPE, TPO, TPU, TPV, TPR)

- PVC

- Nylon

- Acrylic

- Acetal

- Ethylene Vinyl Acetate (EVA)

- Polyethylene (HDPE, LDPE, LLDPE), Polystyrene (HIPS, PS),

- Polyurethane(PU), Polypropylene(PP), Polycarbonate(PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Epichlorohydrin (ECO)

- Teflon & glass filled material

ROTATIONAL (ROTO) MOLDED (USE SOLAR PLASTICS PRESENTATION)

- 16 rotational molding machines

- 3 5-axis routers

- Post Mold Foaming

- Complete Assembly Capabilities

Materials

- Polyethylenes

- XLPE

- Rotolining

- Polypropylene (PP)

- Polyurethane Foaming

- Nylon 6

- Nylon 11

- Nylon 12

- Color

- UV Stabilizers

- Flame Retardants

- Foaming Agents

VACUUM FORMING / THERMOFORMING

- Vacuum Formers/Pressure Molders with 6 Axis Trimming Equipment

- Process Capabilities from Hard Plastic Parts (i.e. ABS) to Complex Multiple-Laminates or TPO’s (Headliners)

- Flame Laminating Capabilities

Materials

- Flex Barriers

- Sound Absorbing Polyurethane Foams

- Acoustical Textiles

- Sound Absorbing Laminates

- Insulating Materials

- Pressure Sensitive Adhesives (PSA)

- Open and Closed Cell Materials